Energy Savings Tips

For your machine operation: Simple and easy to implement

Energy efficiency is one of the most significant challenges for companies worldwide. In light of global developments, the efficient use of energy has evolved from a often neglected goal to an unavoidable necessity. Sustainability and climate protection are existential issues, increasing energy costs intensify economic considerations, and awareness of social responsibility is growing.

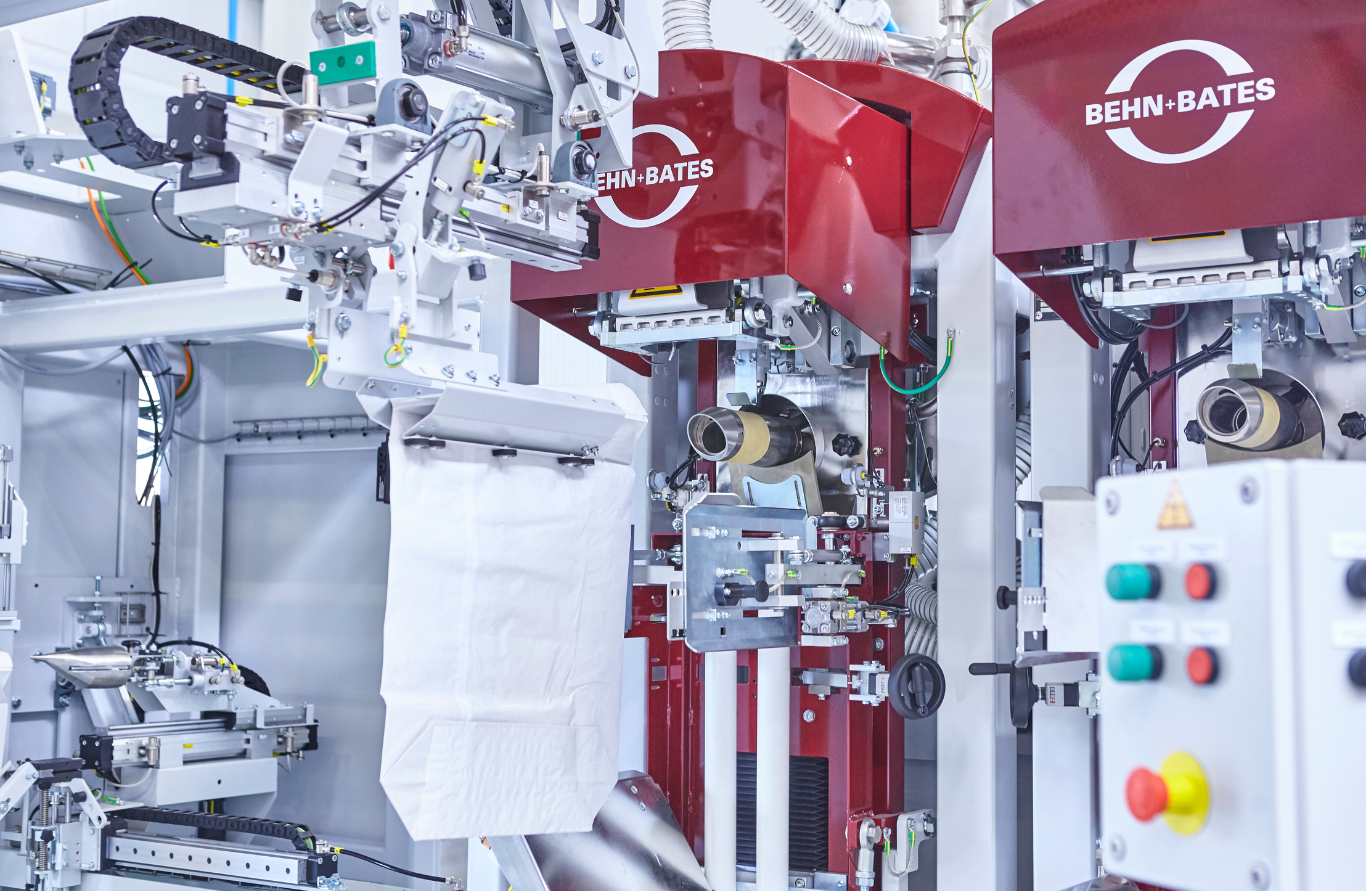

For the packaging specialists at BEHN + BATES and HAVER & BOECKER Maschinenfabrik, developing and utilizing various saving potentials is always a top priority. Our approaches range from pure service measures for process optimization, to the modernization and retrofitting of existing plants, to the optimization of controls and the targeted acquisition of packing technology, packaging materials, or automation technology.

Your infographic on saving energy

Download today!

Keep our energy tips in mind at all times! Place them in your workplace, on your office wall, or on your desk. This way, you can operate sustainably while reducing costs. To fill out the form to download the infographic, please visit the HAVER & BOECKER website.

More with less

Our approaches explained simply

High performance for maximum results

A crucial factor for energy efficiency in production is optimizing machine performance and availability. A system operating at consistently high output, precise weight accuracy, and minimal downtime saves significant costs, reduces energy consumption per sack, and lowers costs per ton. Demand-driven automation, from fully automated bag placers to logistics, maximizes efficiency.

Energy waste occurs when only part of the filling spouts are in operation but a basic energy requirement is still needed. BEHN + BATES identifies inefficient processes and optimization potential during service interventions, implementing targeted measures. This includes optimal system tuning, coordination of all ancillary equipment, and ensuring uninterrupted supply of consumables.

More safety, less downtime

Downtimes in the packaging line can be minimized through continuous monitoring and preventive maintenance. With digital tools such as the QUAT²RO® System Monitoring from HAVER & BOECKER, production processes and maintenance statuses can be monitored and analyzed globally. This allows for quick identification and resolution of irregularities.

Performance data available at any time enables maintenance to be planned at an early stage, allowing maintenance work to be optimally integrated into the operating process and sudden breakdowns to be minimized.

Automatic shutdowns of peripheral systems offer significant energy savings; when the automatic bag applicator stops, other machines are promptly shut down.

Additional software solutions like our QUAT²RO Production, QUAT²RO Batch, and QUAT²RO Logistics ensure efficient process management, enabling maximum results with minimal energy consumption.

Using resources cleverly instead of wasting them

Unnecessary material loss often accompanies high energy consumption. Through precise filling technology, efficient material recycling, and improved product protection, BEHN + BATES significantly reduces waste. Innovative solutions like ROTO-LOCK®, ROTO-FEED®, and SEAL technology not only minimize material losses but also reduce operating costs through lower wear and maintenance needs.

ADAMS® technology allows for filling into dense, recyclable PE FFS bags that protect your food products from moisture, reducing storage and shipping costs. Additionally, optimized drive sizes and frequency converters help significantly lower energy consumption in production.

BEHN + BATES offers tailored solutions for servicing, upgrades, and new installations, supported by comprehensive expertise.