Today, more than 800 million people in the world suffer from hunger. Crop failures due to environmental influences, conflicts and crises as well as poverty are the main causes. But a world without hunger is possible. The natural resources, the knowledge and the technologies are available.

The sustainability goals can be achieved if governments, businesses and all citizens work hand in hand on achieving them. Specific measures to achieve food security include the sustainable design of all food systems from production to consumption, minimising food waste and ending poverty.

We want to make our contribution to this.

ZERO HUNGER

For a world without hunger!

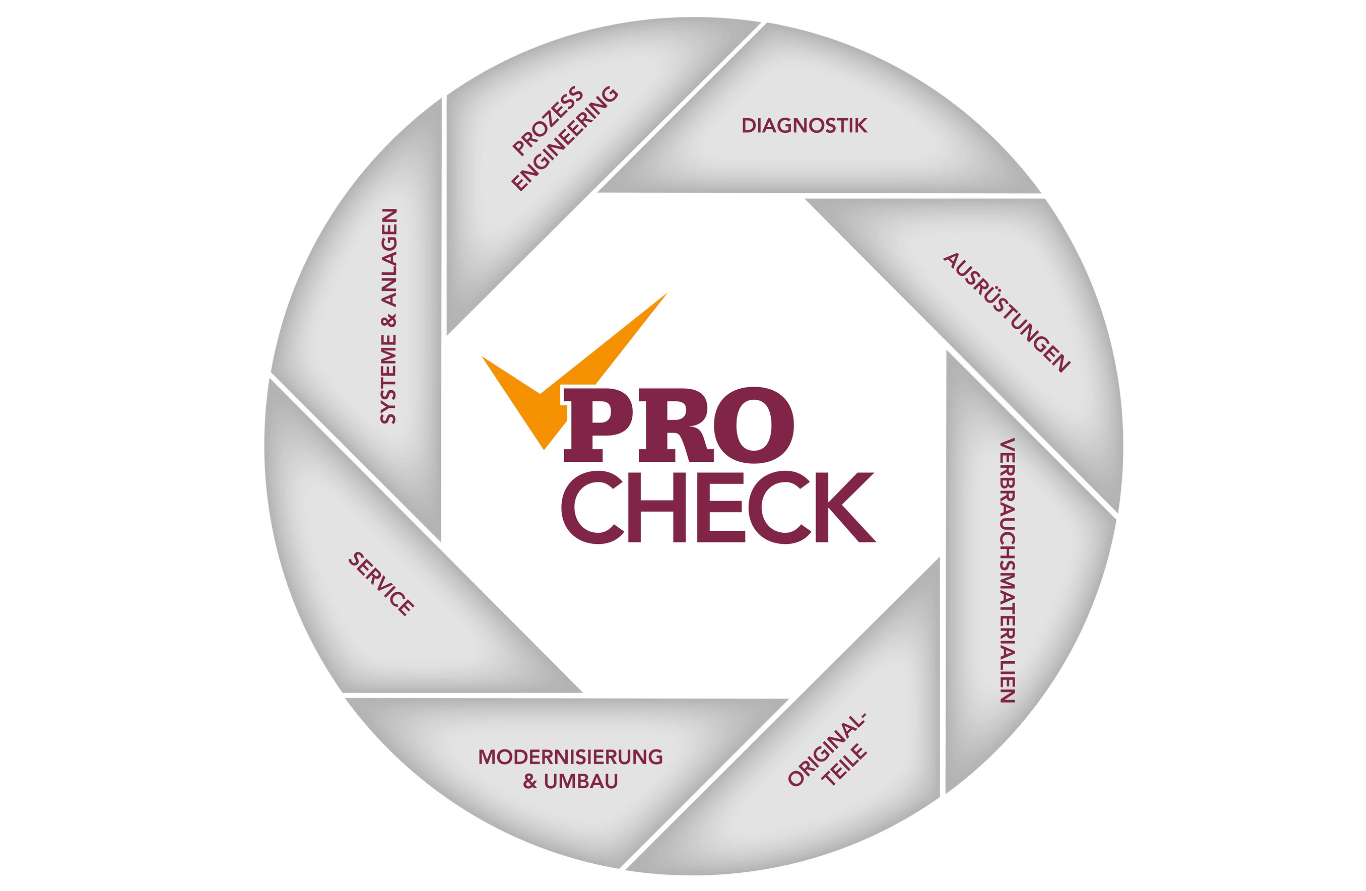

As a company that packages food products, we see it as our responsibility to protect and preserve them. With our expertise, machines and services, we are making our contribution to a world without hunger. But we are just at the beginning - we will develop further concepts for products, the environment, people, technology and the region to support the ZERO HUNGER goal by 2030.

An optimal packaging serves to protect food from external influences, increase its shelf life, and prevent contaminated or spoiled food. A wide variety of packaging materials can be processed with our filling techniques - depending on the application and required shelf life, these can be paper, plastic or aluminium bags.

For a longer product shelf life, it's often necessary to execute the packaging as tightly as possible and pack the products with the least amount of residual air. Our filling technology is designed for this challenge, for instance, through the use of a venting filling tube in valve sack technology or the specialized ADAMS® filling technique for dense and double-layered PE bags. This ensures maximum product protection from filling to the end consumer.

Sustainable concepts for both machines and consumables are becoming increasingly important nowadays in order to conserve our increasingly scarce resources.

This is how we contribute to ZERO HUNGER:

Our machines are designed for long service life. Through regular maintenance and the option to upgrade machines to the latest technology, we ensure maximum durability. Used machines are exchanged in high-tech regions and reused in countries with a lower degree of automation. We are constantly working with our partners to further develop bag materials in terms of their recyclability and a sustainable circular economy.

In order to protect our environment and enable every person on earth to live a dignified life, we must use natural resources sparingly. The reduction of product loss, use of recyclable bag materials and reduced energy consumption are the focus of our further development.

Thanks to our modular design, the packing machines are designed for the actual production volume required and can be adapted or expanded at a later date. The long service life of our packing machines and the use of components that reduce energy consumption and material wear also stand for the careful use of resources and materials.

Through the use of our machine technology, we reduce the loss of food during filled until it is used by the consumer. Our machines fill your food reliably with virtually no loss, e.g. by using our inflatable sleeve, which completely seals the bag valve during filling. The materials extracted during filling are fed back into the production process. Automatic residue emptying systems collect product residues when changing types. With our SEAL technology, the filled bags are hermetically sealed so that even the smallest particles of the product cannot escape. Particularly tear-resistant bags protect the food all the way to the end consumer. Our machines process different types of bags safely and reliably.

Our machines are specially designed for filling food and fullfil the hygiene standards in food production - as well as the highest hygiene standards. They are certified in accordance with the Explosion Protection Directive. This level of protection and clear operation are implemented in all the systems we supply, so that employees in every country in the world can work safely with our machines. At the same time, low dust and noise emissions protect employees from excessive exposure. Our CARE-LINE edition sets standards in this respect. It is suitable for filling baby food under stricter hygiene regulations to prevent microbiological contamination. This means that all children can have safe access to nutritious food.

As a medium-sized company, we see ourselves as part of a social tradition and a responsibility for a sustainable world in which everyone has access to food. We are already contributing to ZERO HUNGER with our machine technology. We also support charities and projects to combat malnutrition and undernourishment in crisis regions. We are constantly expanding our product range in order to improve working conditions in the upstream stages of the food chain. This is achieved, for example, through newly developed devices that reduce the risk of injury on the plantations when harvesting cocoa fruits. Education is an important factor. We need to train people so that they have job prospects and can feed themselves adequately. We promote training and education programmes and create added value directly on site through partnerships for education. Together with our employees, we are looking for further opportunities so that everyone can get involved. Because we can all take action.

Together we are shaping a future without hunger - are you with us?