Automation for packing systems (Digitalization)

Enjoy making a system work for you instead of working for your system

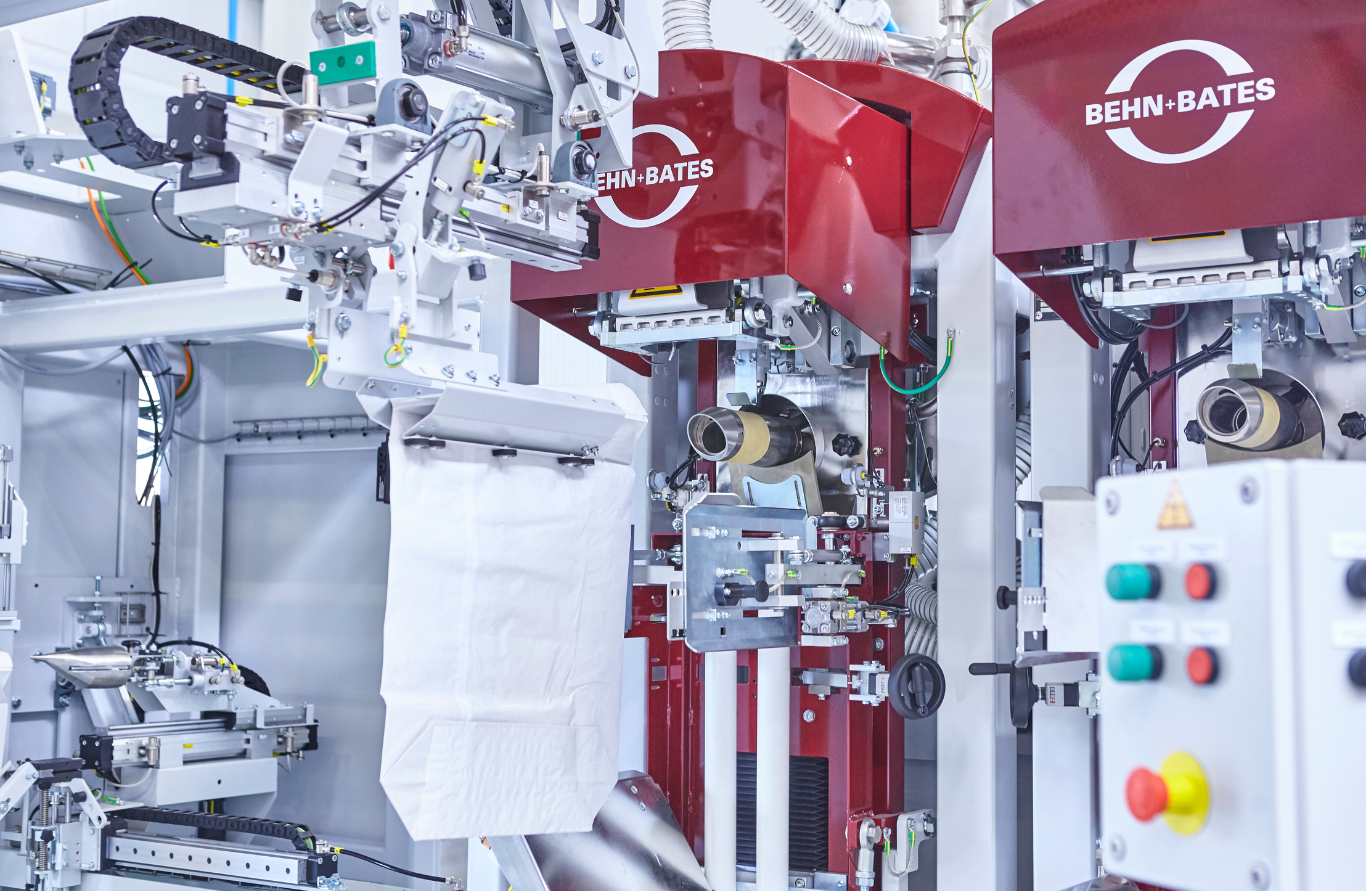

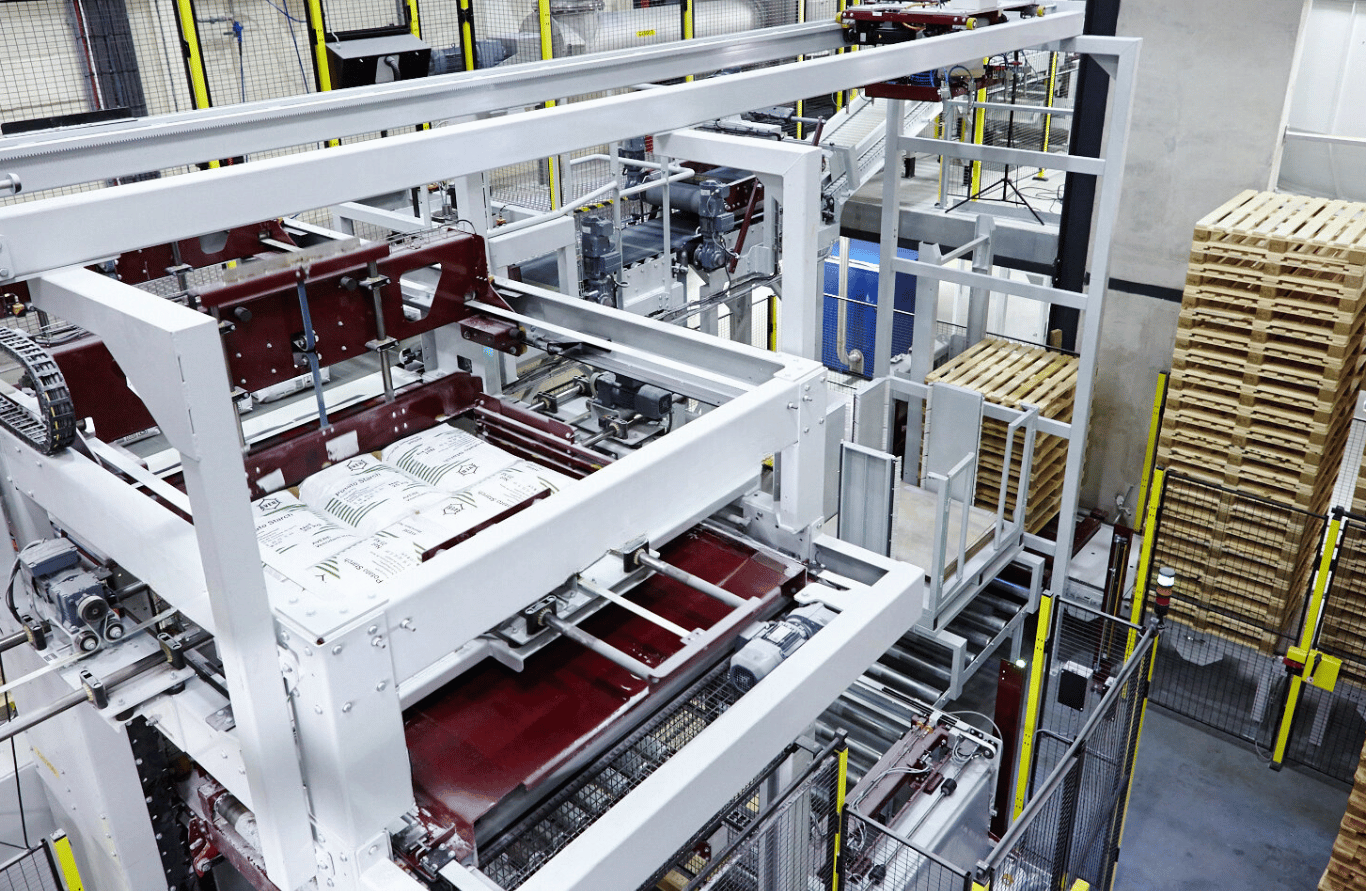

Our packing systems stand for top quality and reliability. Nevertheless, occasional disruptions may occur. In such cases, quick action is required - and this is exactly where we come in with our automation systems!

By networking the machines, potential downtime risks are significantly reduced. Our highly intelligent systems provide automatic and reliable data that can indicate possible maintenance requirements. At the same time, you will gain in-depth insights into aspects such as machine productivity and rejection rates. Make full use of the wide range of digital options for monitoring, controlling, analyzing and optimizing your processes.

Together with our sister company QUAT²RO we use smart digital product solutions to ensure that every process step within your production is monitored in real time, from the original product to the finished, ready-to-transport pallet. This comprehensive transparency minimises potential risks and ensures that your production times run smoothly. This means you can be sure that there are no unexpected surprises and that your processes are continuously optimized and efficiently designed.

Our software solutions include:

- Individually tailored software packages through to complete packages for the entire value chain

- Optimization of your production through improved condition monitoring with real-time data tracking and storage and intelligent automatic parameter adjustment

- Increasing data transparency and improving data analysis through continuous production data acquisition

Users confirm

Our data management systems score with

- Reduce system downtimes by monitoring the production performance of your machines in real time

- Cost reduction through early detection of disruptions and proactive planning of maintenance intervals based on machine data

- Increased efficiency through the comparison of different machine data

- Optimization of resource planning