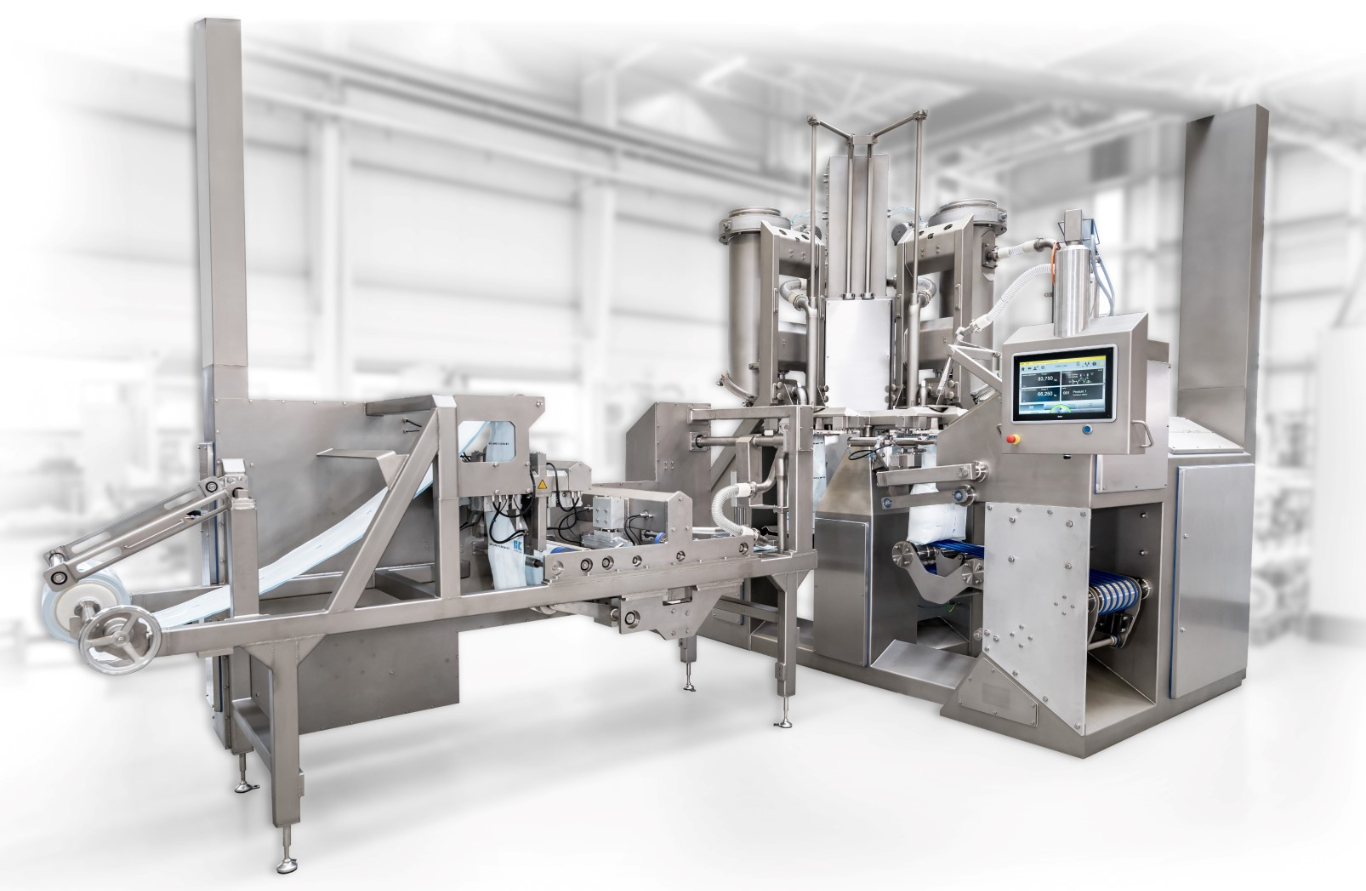

Packing machines for FFS bags

How to ensure cleanliness and efficiency in your packing operation

The packaging of your quality products must fulfil various requirements. It should be clean, compact, accurate in weight and easy to store in order to optimally protect your product. The Form-Fill-Seal (FFS) bag fullfils these requirements to the highest degree. It is formed from a gusseted tubular film, filled and sealed. The bag size is thus optimally adapted to your product and film consumption is reduced.

Initially, only granulates could be reliably and safely filled into FFS bags, but nowadays filling is also possible for powders thanks to refined and sophisticated technologies. We have various machine types that differ in terms of the type of product dosing, filling and deaeration as well as the available output ranges.

Users confirm

This is why our packing solutions for FFS bags stand out

- Productivity, flexibility and availability through our modern, low-wear, and low-maintenance machine technology

- Clean and weight-accurate product processing thanks to our product-specific dosing system

- Excellent product protection against moisture and external influences

- Low costs thanks to a clean packaging environment, low cleaning costs and optimized intelligent maintenance

- Environmental friendliness through precise packing and thus reduction of packaging material, recyclable materials as well as a high recycled content in films and composite materials

- A perfect appearance through use of sophisticated bag printing with possible gloss effects - for high customer acceptance

Under the motto "WE TAKE CARE", our BEHN + BATES experts developed the ADAMS CARE-LINE EDITION - a packing solution that combines proven components with EHEDG guidelines under new hygiene aspects. The special feature is that the most hygienic packaging material for highly sensitive food - airtight PE film bags – is filled reliably.

Your advantages at a glance

- Maximum cleanliness due to the use of completely encapsulated components, as well as rounded corners and bevelled edges

- Maximum weight accuracy through use of separate coarse and fine flow dosing

- Reduced maintenance efforts due to continuous gentle operation of downstream aggregates

- A compact bag shape due to corner welding for stable side gussets and head air extraction before sealing the filled bag

- Easy operation thanks to the clearly laid out touch panel and the open and accessible machine design for quick cleaning and maintenance

Top marks for product protection, logistics and product presentation - the FFS bag formed from an endless gusseted tubular film meets these requirements. Our ADAMS technology for powder guarantees:

- Optimum bag preparation by cutting off the film length required for your product and subsequent bottom seam and corner welding

- A clean filling thanks to the dust-tight BEHN + BATES powder filling spout, which fills your product according to the gross system via air or impeller units

- A clean and efficient overall result due to internal and bottom vibrators for optimum product compaction in the bag

Your advantages at a glance

- Compact bag shapes due to simultaneous bag filling and compaction as well as integrated corner welding

- The highest tensile strength of modern – even the thinnest – films to avoid bag breakage in the entire logistics chain

- A compact machine design that not only stands for efficiency and space saving, but also fulfils the strict hygiene standards of the food industry

A guarantee for maximum performance and convenience when filling granulate into FFS (Form-Fill-Seal) bags – that‘s what the flexible FFS systems produced by our sister company AVENTUS stand for:

- TOPAS SF - the high-performance machine for high-end applications (over 2,800 bags/h in real packaging operations);

- FFS 600 - the flexible design for multiple applications (up to 550 bags/h).

The two design variants are compact, fully enclosed packing machines for filling grains and granulates. They also work according to our proven Plug' n Pack principle, so they only need to be connected and adjusted for your product. The filling can already begin.

Your advantages at a glance

- Space-saving, high-performance and robust machine design

- Easy operation and maintenance due to clear and intuitive user guidance

- High user-friendliness through a clean packaging environment, good machine accessibility, and low noise levels

- High flexibility due to mobile machine design and easy transition to other product and film types