Check-up

Prepare your packing machine optimally for current challenges

The healthy operation of your packaging machine is paramount when aiming for long-lasting efficiency and productivity. Just as you rely on your packaging machine, your valuable asset - the machine - should also rely on you as an operator. Therefore, regular check-ups are essential.

For maximum productivity

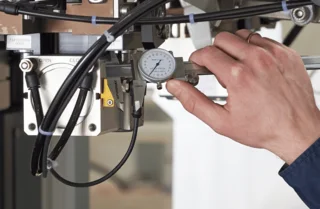

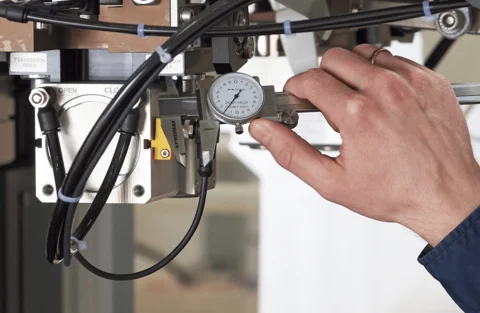

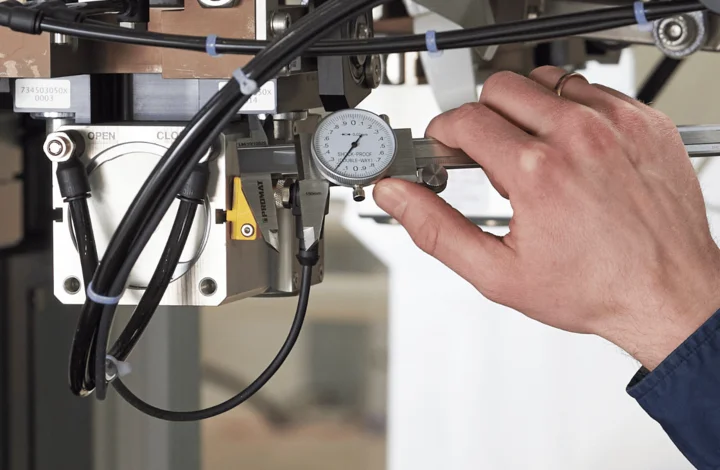

Our service experts take a close look at all the components of your packaging machine, such as pneumatic parts, in order to optimise reduced energy consumption. They also ensure that all processes are perfectly coordinated, which means that the packaging process runs smoothly and cleanly.

The advantages for your packing operation:

- Stable performance

- Efficient utilisation of resources and operating materials

For the best possible machine availability

For optimal machine availability, our experienced service experts conduct regular check-ups, such as within a preventive maintenance schedule, to identify potential weaknesses in your packaging machine. They spot hidden defects that could lead to a breakdown sooner or later. They also uncover signs of wear and advise on components that may need replacement in the near future. Subsequently, we perform the necessary overhaul work on your machine, always in close consultation with you.

The advantages for your packing operation:

- Avoidance of unexpected production downtimes

- Extension of the service life of your machine

- Increased efficiency

For reliable delivery capability

Do you have the essential original wear and spare parts in stock? Please bear in mind that delivery times may unexpectedly become longer than usual due to adverse circumstances. Although we have many common parts in stock and can guarantee prompt delivery in most cases, we are still dependent on global market conditions. It is advisable to prepare for this at an early stage and adapt your spare parts stock accordingly.